This post is going to cover how to build a shower pan for tile using two different methods.

The first method is an “old-school” method that has been used for decades and the second is a newer system that is simpler, and some feel a better design.

Whichever method is preferred the important thing is to build your shower pan correctly and always perform a flood test on it to make sure it works properly.

Estimated reading time: 8 minutes

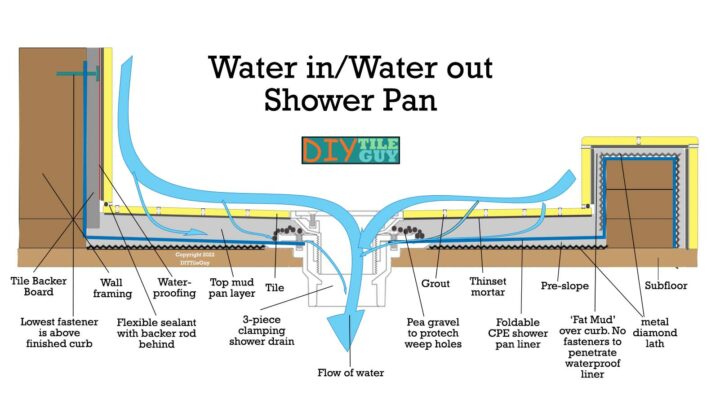

Water In/Water Out

What has become known as a water in/water out (WIWO) shower system is the method for building shower pans that has been around for decades.

I would estimate that this is still the most commonly installed shower in the USA today.

The WIWO shower is a traditional liner and mud bed system. Most of the traditional liner systems are installed with backer board these days particularly, cement board or Hardibacker.

However, in previous years, and to a lesser extent now, they were installed with “mud” walls and chicken wire. This means that the walls were formed out of a sand/cement/lime combination and then tiled over.

Whichever way they are done you want to make sure the shower walls are waterproofed correctly, as well as the shower pan.

How a water in/water out shower pan is built

The way these systems are built is they have a mortar bed that allows water to flow through it. This water then finds its way down to a rubber-like shower pan liner.

Further, the shower pan liner is sloped so that the water evacuates down the 3-piece clamping ring shower drain. This clamping ring contains weep holes to let water escape.

Waterproofing materials for water in/water out shower floor

- Shower pan liner (Made from CPE or PVC is most common today)

- Hot mop (still done in certain areas)

- Copper tray

- Lead pan

These days, foldable rubber-like liners are most common for managing shower water. Less common is the hot mops which are comprised of hot asphalt.

Finally, in really old homes that haven’t been renovated, you may still find a copper or lead pan underneath the shower floor.

Advantages of water in/water out shower system

These are the main advantages of water in/water out shower pans:

- Materials are inexpensive

- Long track record of proven performance

And the disadvantages are:

Disadvantages of water in/water out shower system

- Requires some skill to install

- Can take more time to complete

- No industry-accepted method for building curbless showers

As proven and popular as the WIWO shower is there has been some innovation in the shower building field. That’s where the sealed shower systems come in.

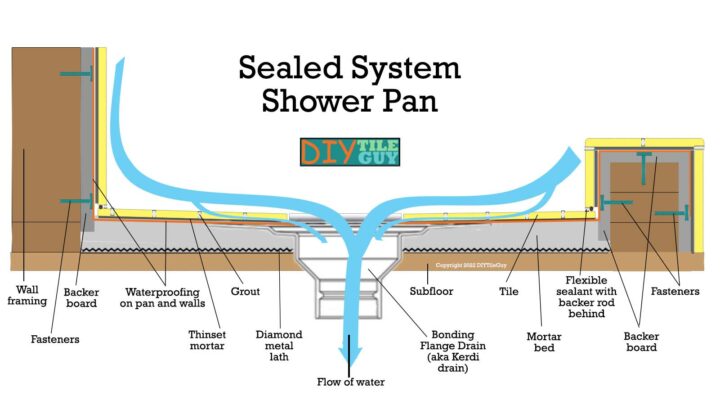

Sealed Shower Systems

What we are now calling the ‘sealed shower system’ was popularized by the Kerdi Shower System. This shower system was created by a German company called Schluter Systems.

The idea behind the sealed pan is that, rather than let the water absorb into a cement layer, it stops water at the surface, immediately below the tile and adhesive layer, and sends it down the drain.

In addition to the Kerdi system, there are several other brands available such as Hydroban, GoBoard, Wedi, and others.

How a sealed shower pan is built

Typically, the shower floors will be either a mortar bed or an XPS foam shower pan that is pitched to the drain.

Then a thin waterproof membrane is bonded to the sloped foam or mortar bed. These systems typically incorporate a special kind of shower drain called a “bonding flange” drain that the waterproof membrane marries to.

Check out my post on the 4 best bonding flange drains on the market. Additionally, there are some linear drains that are designed to work with sealed shower systems, such as the Noble Freestyle Linear Drain.

Tile then adheres directly to the waterproofing membrane,

Waterproofing materials

- Bonded CPE membrane

- XPS Foam

- Liquid-applied or trowelable waterproofing

The original Kerdi system had a waterproof fabric that you installed either over a mud bed or over their foam shower pan.

Now most shower systems have the waterproofing fabric already attached to a foam pan.

Further, some even allow for liquid-applied or trowelable waterproofing membranes. These are advantageous with odd-shaped pans that curve around radiused shower benches or walls.

Advantages of sealed shower system

The advantages of sealed showers are:

- Faster installations

- Requires less skill

- Good method for a curbless shower

Sealed showers usually can be built faster because you don’t have to build a pre-slope out of cement. So, it saves a step and some drying time.

Further, they are particularly fast if using a preformed foam shower pan.

Disadvantages of sealed shower system

- Materials cost more

The main disadvantage of this type of system is the cost. These shower systems are built by particular companies, carry their branding, and usually have some sort of system warranty that incentivizes using all of one company’s products.

Which is the better way to build a shower pan?

Which system is the better way to build a shower pan depends on who you talk to.

Newer installers tend to prefer the sealed shower system approach. This may be because they’ve never been trained on all the little but important steps of a water in/water out shower.

Perhaps, the manufacturer’s marketing of the newer systems touting their advantages makes the sealed systems more desirable.

Older installers may prefer a WIWO shower as that’s what they know and they distrust new products.

Bottom line

Both the sealed shower system and the water-in-water-out system work. Both are recognized by the tile industry as acceptable ways of building a shower and managing the water.

However, it’s critical that the instructions are followed for each system. Failures in these systems are nearly always caused by installation errors.

Read this post if you want to know how to calculate how many tiles you need for a shower pan.

FAQ about How to Build A Shower Pan

Shower floors should be made out of a sand/portland cement mixture that allows water to flow through it. Concrete doesn’t allow that process to happen and therefore shouldn’t be used for building a tiled shower pan.

The material that tiled shower pans are made from is referred to as ‘dry-pack’ mortar and is a 4 to 1 or 5 to 1 sand and portland cement mixture

The minimum slope on a tiled shower pan is 1/4 inch of fall for every foot in length. The maximum amount of slope is 1/2 inch of fall for every foot in length.

In addition to dry-pack mortar shower pans, you could opt for a preformed shower pan. Many are made from foam or polyurethane and come ready to tile.

Improper installation of a tile shower pan is, by far, the most common cause of failure.

When it’s properly built, the Kerdi System is a good, sound system for building a shower. I talk more about why some incorrectly feel the Kerdi system is flawed.

Although hot mopping is still done in some specific areas most tile shower pans are built with membranes as they will have a longer life.

Wire mesh is not needed in smaller shower floors under 60 square feet.

In addition to the Kerdi drain, there are several different types of bonding flange drains on the market that you can compare.